europaddle.com

NEW Gen 4 Pickle Ben Johns Perseus Pro IV 16mm Pickleball Paddle GEN 4 TFP Foam Core With Toray T700 Carbon Fiber Surface

NEW Gen 4 Pickle Ben Johns Perseus Pro IV 16mm Pickleball Paddle GEN 4 TFP Foam Core With Toray T700 Carbon Fiber Surface

Couldn't load pickup availability

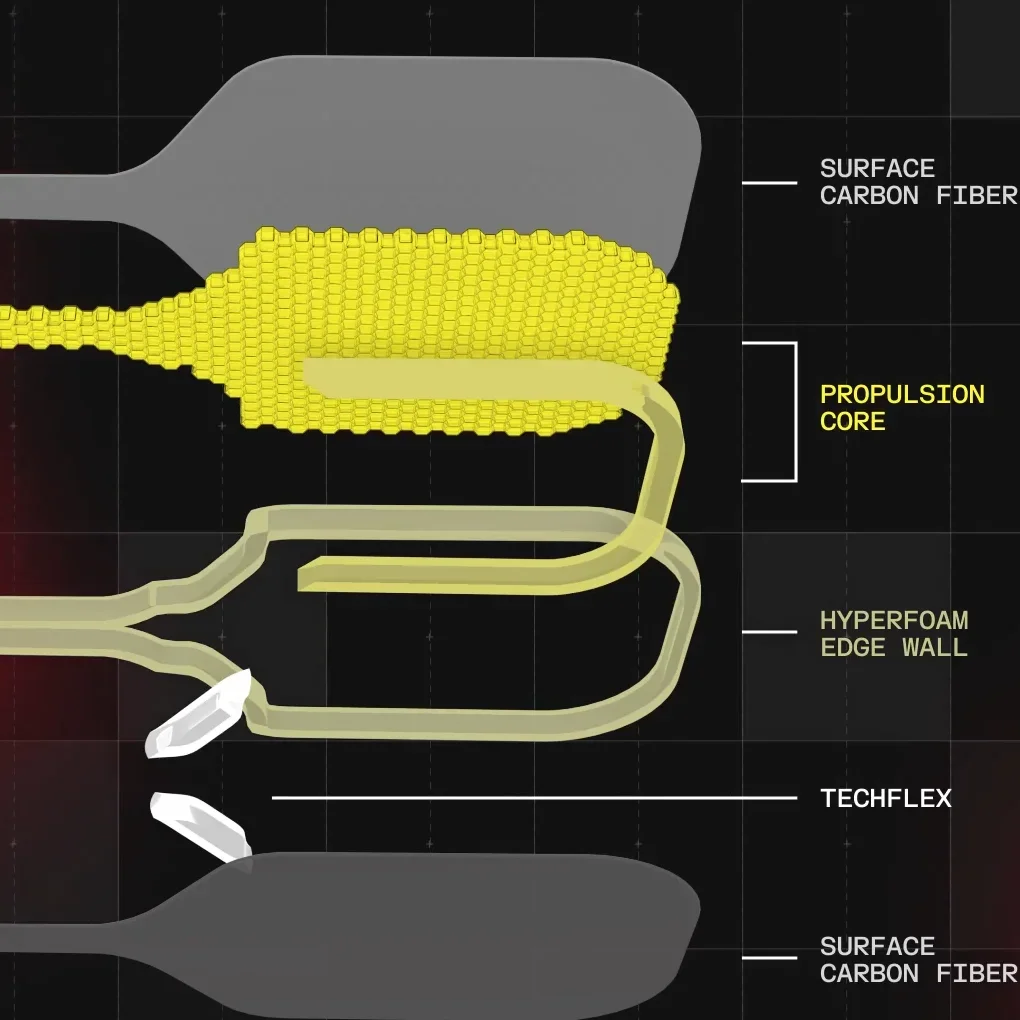

The Perseus Pro IV pickleball paddle is the ultimate blend of innovation, control, and power. This next evolution of our beloved paddle shape now TechFlex Power (TFP) technology, resulting in improved precision and more confidence with every shot. The optimized weight distribution within the Perseus Pro IV reduces paddle fatigue and provides forgiveness on mishits - giving you more room to play your individual game. The Ben Johns Perseus Pro IV 16mm pickleball paddle is UPA-A pro Certified and USAP PBCoR .43 Certified.

Please pay attention to this

1: Just OEM Pro Pickleball Paddle but not with out brand logo

If you want a paddle use similar Brand can buy it , But if you want brand logo please don't buy .

2: All order will shipped within 24 hours , will arrived asap

3Perseus 4 use TFP technology the same with brand , Improve fault tolerance Suitable for players at all stages

4:Because we are a factory, we do not have specially customized color boxes. We only have simple paper box packaging

item |

value |

Place of Origin |

China |

Guangdong |

|

Model Number |

Hyi-16mm Perseus |

Material |

Carbon Fiber, Toray carbon Fiber |

Brand Name |

Hengyi |

Age Group |

Children, Adults |

Usage |

Entertainment, Racing, Training |

Paddle Length (inch) |

16.5 |

Handle Length(inch) |

7.5 |

Weight (g) |

230g+/-5g |

Product Name |

Perseus/Magnus/Hyperions/Scorpeus 4 16mm |

Material |

Toray Carbon Fiber |

Logo |

Accept Customized Logo |

Color |

White |

Core Material |

8mm PP Polypropylene Honeycomb Core with EVA Foam +TFP Foam Core

|

Certificate |

UPA-A Certified+USAP PBCoR .43 Certified. |

Size |

16.5*7.5 inch |

RZ/RT Value |

Close 30/40 |

Material:Carbon Fiber

Length (cm):419mm*190mm*16m

Maximum Spin

Model Number:magnus

Material:Carbon Fiber

Length (cm):419mm*190mm*16m

Maximum Spin

The interior is filled with 8mm polymer honeycomb , Surrounded by a white EVA foam.

The composition structure of the carbon fiber plate is composed of 3 layers.

After the carbon fiber plate is glued to the honeycomb, it is put into the mold for thermoforming.

After 25 minutes of thermoforming, we can get a semi-finished 360-degree GEN3 pickleball paddle.

Next, we print the surface pattern. Assemble edge guard strips and GRIPS. We end up with a finished GEN3 pickleball paddle.

When glass fiber is added to the surface of the carbon fiber plate, paddle will have more control and spin in use.

The EVA foam filled propulsion core will make the paddle have more powerful resilience.

GEN3 paddle will give you a great experience in pickleball games.

16.5*7.5 inch fan-shaped top and 140mm has lower wind resistance and is suitable for backhand forward attacks,

Surface materials are commonly divided into three categories: glass fiber, carbon fiber, and Kevlar

Among them, carbon fiber is divided into several categories based on strength, namely T300, T700, T800, T1000, 3K, 12K, and 18K

Step4 Thermoforming

Place the pre formed honeycomb core and

Share